With a PWM controller, this board allows very fine adjustment of the energy supplied (and thus the speed of rotation of the axis) to an electric motor, both when loaded. The adoption of a special sensor integrated MOSFET can suspend supply current when the engine uses too.

SPECIFICATIONS

- Food: 12 to 24 VDC

- Maximum current output: 10

- Designed for low voltage motors

- Frequency adjustable from 300 Hz to 2 kHz

- Protection in adjustable current between 0 and 10 A

- Speed adjustable between 0 and 100%

- MOSFET with integrated current sensor

- Motor voltage: 12 to 24 VDC

- Dimensions: 15 x 8.5 x 2.5 cm.

Component technology and design techniques are constantly evolving and fixtures that we offer are in the refl ection. The variable speed drives for DC brush that is the subject of this article is a good example: the component that constitutes the heart is a remarkable innovation. The controller couples to the traditional technology PWM (pulse width modulation) current limiter operated by the fact that the MOSFET, which is confidential ed food impulse motor has an auxiliary terminal can provide a current whose intensity is proportional to that passing through the drain-source. A component belonging to a new class of "Power-MOSFET" (produced by International Rectified st) and is controlled just like a traditional or IRF540 BUZ10, etc..

The setup proposed here will suit anyone who wants to control the speed of rotation of the axis of an electric motor: the regulation is quite specific because it is based on the amplitude variation of the voltage applied to motor brushes connected to points "OUT" or the power delivered. This regulation is achieved by sending the motor current pulses whose duration is directly proportional to the desired speed. Compared to the control voltage, output pulse amplitude equal to those whose engine needs, but of variable width, gives a fairly uniform rotation, even under load because the torque does not change : in fact the axis does not rotate in steps (or facets) but uniformly with an angular velocity dependent, with equal applied load, the pulse-pause ratio of the pulse train supplied by the regulator.

wiring diagram

Figure 1: Diagram of the variable speed DC motor.

Figure 1: Diagram of the variable speed DC motor. The wiring diagram of the fi gure 1 reveals a fairly complex circuit in appearance, but is rather simple. The generator consists of a rectangular pulse width modulation, a voltage translator, a fi nal of power and a floor sensor power capable of intervening on the pulse generator to block. A voltage regulator U2 7809 stabilizes the 9 V power to the circuit required: indeed, this voltage powers the PWM controller and current protection, which require reference potentials, require good stability. Thanks to the venerable fi ltering capacity obtained with C7, C8 and C10, U2 is a wall that peaks and voltage drops due to the MOSFET switching on the motor armature can hardly pass. The fuse operates, cutting the main supply line when the circuit or the engine tends to consume more current than the limit allows.

The heart of the PWM generator is achieved by coupling a particular astable multivibrator and a comparator operational amplifi er: in effect, to produce the pulse width modulated, we compare a potential continuous waveform almost triangular produced by a pin of U1, a mounted con.guration NE555 astable. This timer produces a square wave loading and discharging a capacitor inserted in the network delay, that is to say, by allowing it to charge through R1, D1, R2 and R23, then discharging it through R2, R3 , R23 and D2, when the logic level of the output is inverted. Pin 3 is unused, is not on the diagram.

The exponential component is taken across C1: comparison, devoted to the operational U3a (confi inaugurated as a comparator), the quasi-triangular waveform (pin 2) and the voltage fed to the pin 3 and T4 trimmer R24, determines the output (pin 1) a rectangular waveform whose duty cycle depends strictly on the amplitude of the voltage due precisely to T4 and R24.

See how the comparator: the output is at logic high (about the potential of the positive supply) when the value of this component across C1 is lower than that applied to pin 3 and, conversely, starts at about 0 V when the voltage taken from the quasi-triangular astable takes more amplitude than the reference potential. It follows that the duty cycle is directly proportional to the amplitude of the voltage delivered by T4 because if it increases, the periods during which the pin 2 is positive with respect to 3 are reduced, and the length of pauses between two consecutive pulses of the rectangular wave. Of course we are talking about relative pulse / period of the outgoing component of the spindle 1 because, at the exit, that is to say the motor terminals, the situation is reversed: the higher the voltage reference smaller the width of current pulses produced.

The diagram shows that the reference is obtained from the operational through two components: a fi xed potential, configurable when setting a variable and R24 from the circuit current limiting output.

To understand the functioning of the latter, we need to know where is fi ne the wave generated by the PWM comparator.

Pin 1 drives the power MOSFET Q3 through a translator and amplifier stage consisting of complementary symmetrical T1 and T2 (PNP and NPN, respectively). This circuit provides a behavior equal to the negative half-wave and half wave positive: it produces control pulses perfectly square (with rising and lowering net) to the gate of MOSFET. The collectors of T1 and T2 drivers thus sending impulses to the leg 1 (trigger) of T3. Note that the zener D1 is mounted essentially as extreme protection of the MOSFET for the event, by destruction of U2, the voltage on the supply line regulator exceed 12 V. Each time it receives a positive pulse, the fi nal power conduit between drain and source and thus leaves the current path with hardly any resistance: indeed, its Rdson (measured electrical resistance between drain and source in full conduction ) is typically of 0.077 ohm, which n'infl uence not the voltage applied to the motor.

At the same time the pin 2 through R18 is a current directly proportional to browsing the motor windings and therefore the drain-source circuit, which allows the limiting stage to play its role. Against each positive pulse at the terminals of R18, another pulse is created (in phase and duration proportional to the current product): the result is a rectangular waveform which, properly fi lter by a low-pass cell ( R17/C9) becomes a continuous component, then sent to the second operational U3 (a CA3240).

U3B is the element in the system, decides when the current protection must be made: by suitably regulating the R25 trimmer is in setting the switching threshold and hence the level that the current supplied to the engine can achieve without the regulator to suspend the production of pulses.

It goes without saying that the greater the potential on the cursor of the trimmer, the higher the intensity allowed in the MOSFET and vice versa. For precise operation and effi cient triggering protection, we made stable switching threshold by feeding R25 through a resistive network whose voltage is stabilized by D3 (polarized directly it gives exactly 0.7 V). In addition, the comparator with hysteresis is of type. Rétroactionnant feature obtained in the positive operational U3B: thus, once reached the limiter, the current discharged by the MOSFET must fall below the value that caused the outbreak, if the output stage allows the engine off.

Let's see one last thing: how the protection operates. The output of the command U3B NPN T5 mounted inverter logic and interface to the control stage. Its collector supplies the base of PNP T4. We can see that when the current in the motor exceeds the limit threshold set by R25 and pin 7 of the CA3240 from the high logic level, strength T5 saturation, the current in the collector may be determined to R20 ends of a potential difference sufficient to saturate as health T4. Its collector current, carried towards R7, raises the potential reference U3a to a level higher than the maximum attainable by almost triangular wave, which prevents the output of the comparator to the logic low level and to drive the MOSFET Output T3.

Ultimately, when the level set as the limit is exceeded by R25, U3a passed the state of its pin 1 of logic low level to high logic level and holds it there. T1 and T2 is not led by now almost to ground the gate of MOSFET. Note that the drain current missing, the current sensor and also stops at the ends of R18 there is no more voltage drop: the comparator U3B may again raise its output logic level high to logic low, prohibit leaving T5 and T4.

Thus blocking the PWM modulator is released and the MOSFET can restart and carry the load until a new ... any excess power consumption, in which case the protection will intervene again and stop again T3. The current limiting circuit has a dynamic behavior: he is able to "feel" at every moment what is happening to output, that is to say in the engine.

Conclude the analysis with the zener U4, playing the dual role of suppressors of any spikes and reverse polarity suppressor of two phenomena caused by switching ON / OFF "on inductive loads for ment (as are the engines) . In fact, this zener prevents from spreading in the supply line voltages higher than his, and especially of opposite polarity (in this case the zener becomes practically a short circuit).

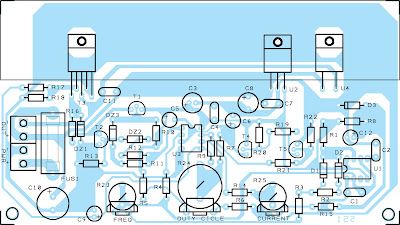

Figure 2: Schematic implementation of the components of variable speed DC motor.

Figure 2: Schematic implementation of the components of variable speed DC motor.  Figure 2b: Drawing scale 1, the PCB of the drive motor speed.

Figure 2b: Drawing scale 1, the PCB of the drive motor speed. Component List

R1 .... 4.7 kΩ

R2 .... 4.7 kΩ

R3 .... 10 kW

R4 .... 47 kilohm

R5 .... 4.7 kΩ

R6 .... 4.7 kΩ

R7 .... 10 kW

R8 .... 4.7 kΩ

R9 .... 470 kΩ

R10 .. 6.8 kΩ

R11 .. 3.9 kΩ

R12 .. 3.9 kΩ

R13 .. 6.8 kΩ

R14 .. 10 kW

R15 .. 220 Ω

R16 .. 220 Ω

R17 .. 1 kΩ

R18 .. 220 Ω

R19 .. 10 kW

R20 .. 4.7 kΩ

R21 .. 10 kW

R22 .. 10 kW

R23 .. 25 kΩ trimmer

R24 .. trimmer 10 kW

R25 .. 1 kΩ trimmer

C1 .... 10 nF multilayer

C2 .... 10 nF polyester

C3 .... 100 uF 50 V electrolytic

C4 .... 100 nF multilayer

C5 .... 4.7 uF 63 V electrolytic

C6 .... 1 uF 100 V electrolytic

C7 .... 100 nF multilayer

C8 .... 100 uF 50 V electrolytic

C9 .... 2.2 uF 100 V electrolytic

C10 .. 1000 uF 25 V electrolytic

C11 .. 100 nF multilayer

C12 .. 10 uF 63 V electrolytic

C13 .. 1000 uF 25 V electrolytic

D1 .... 1N4148

D1 .... 1N4148

D1 .... 1N4148

DZ1 .. 12 V Zener

DZ2 .. 3.9 V zener

DZ3 .. 3.9 V zener

U1 .... NE555

U2 .... L7809

U3 .... CA3240

U4 .... MBR745

T1 ..... BC557

T2 ..... BC547

T3 ..... IRC540

T4 ..... BC557

T5 ..... BC547

Miscellaneous:

2. 2 pole terminal blocks

2. supports 2 x 4

3. bolts 10 mm 3 MA

1. heatsink

1. fuse horizontal

1. 10 A fuse

Unless otherwise specifi cation, all resistors are 1 / 4 W 5%.

The practical realization

We can now proceed with the construction of the device. The plate fits on a single sided PCB whose fi gure 2b gives a scale drawing. When you have before you mount all components initially not going to sink in helping you fi gures 2 and 3 of the list. Then fi xez U4 and T3 on the heatsink (do not forget the insulation kit: bolt nylon + + mica or silicone grease bolt nylon + tefl it alone) and U2 (without insulation kit), so this heatsink on xez the circuit board and fi nally solder all the legs with a small iron and waiting a few seconds between welds. The heatsink (rail aluminum fins with two flat parts) must have a thermal resistance of 4 ° C / W.

settings

Finished editing and verification cations made use, connect the device to the engine and power: battery or AC 230 V capable of supplying a voltage from 12 to 24 VDC and a current equal to at least what the engine consumes to order. But in no case exceed a voltage of 25 V and a current of 10 A.

Afi nd'éviter any problem, we recommend you first connect the power and then, after moving the cursor to its end connected R25 to R5 (counterclockwise) to connect the engine to observe the polarity indicated on the terminal (otherwise it will run in the opposite direction).

Put the cursor button halfway R25 to maintain the current protection off, at least micharge and do the same with the trimming of the frequency (R23). Then turn clockwise until you see the R24 motor shaft turn, then go in the end affect: a comparison you can do so by disconnecting the ls block and connecting them in parallel with food). If rotation begins too late, try to influence the frequency trimmer (R23) by turning his slider in one direction or another, until you find the position allowing the engine to start shooting shortly after the position minimum of R24. The frequency plays an important role as DC motors, when they are controlled by PWM, react differently depending on the frequency of the pulses.

So find the optimal frequency and adjust the trimmer current limiter empirically or by taking a more scientific as: turn off the power then in series with the motor, connect a multimeter (DC, 10 A full scale) reconnect the power and overload the motor to a current increase.

At some point, an indication of the meter must be fi ger on a determined value corresponding to the threshold set: for the modified first, play it on R25 (counter-clockwise: the protection acts to ever lower currents; meaning time: it always occurs for currents closer to the boundary 10 A). Load the engine by preventing its rotation: beware, do not hurt! For example with a drill press DC powered, try drilling a hard material with a large bit (do not try to curb the chuck by hand!).

Figure 3: Photograph of a prototype of the plate drive motor speed.

Figure 3: Photograph of a prototype of the plate drive motor speed. regulator U2, U4 diode and the MOSFET T3 must be fi xed at a sink Rth 4 ° C / W. Between the heatsink and the components must not forget to insert a sheet of mica insulation (coated with white grease, silicone) or TEFL is gray. For fi xing components to the heatsink, use small nylon bolts.

Figure 4: Links.

Figure 4: Links. There are two terminals on the plate with two poles for connecting to the power and motor control.

The drawing also shows the adjustment controls present in the circuit: frequency, duty cycle, current limiting. Their function is explained in detail in the text.

No comments:

Post a Comment